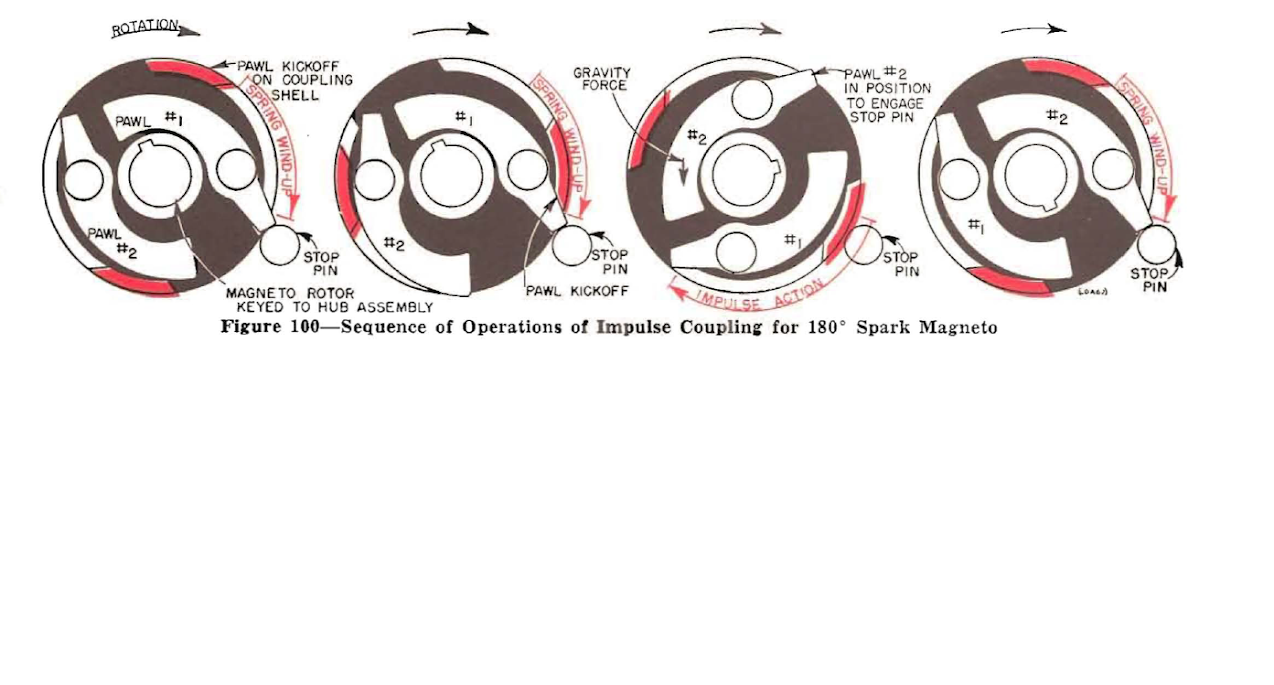

I have experienced kickback several times when hand propping small VW based power plants and due to the painful experiences caused me to look into the cause and see if I could make some improvements.When the engine is running we need the peak pressure within the cyls to happen sometime after TDC..actually we need it about 12-18 deg ATDC to keep it from detonating and still produce power. The reason that our engines fire BTDC is that it takes time for the fuel to burn and produce the pressure. So we have to start it ahead of TDC by about 26-28 deg so that it will peak at the right time for our engines running at ~ 3600 RPM.Now think about it. Running at 3600 RPM it takes way less time to get past TDC than when we are trying to hand start the thing so if you just pull it though and it fires at 26-28 BTDC its gonna snach back.So the impulse coupler is used to delay the spark until the right time when you crank it BUT!!!!! there is a catch. depending on the start speed and the timing setting for the specific engine that the mag was designed for, the lag angle (amount of delay degrees for starting) is different. It may be 15, 20, 25, 30, or 35 deg or some other number.First take a look at how the impulse coupling works in a magneto.  When these engines are put together the magneto is usually a donor from some random application that the engine builder thinks will work. I got to looking at the slick mag on my 4 banger and it is labeled 15 deg. lag angle. so with the mag timed at 28 deg. BTDC if you do the math this means that by turning the prop slowly through by hand the plug will fire at about 13 deg. BTDC. You can see why it would want to snach on ya.

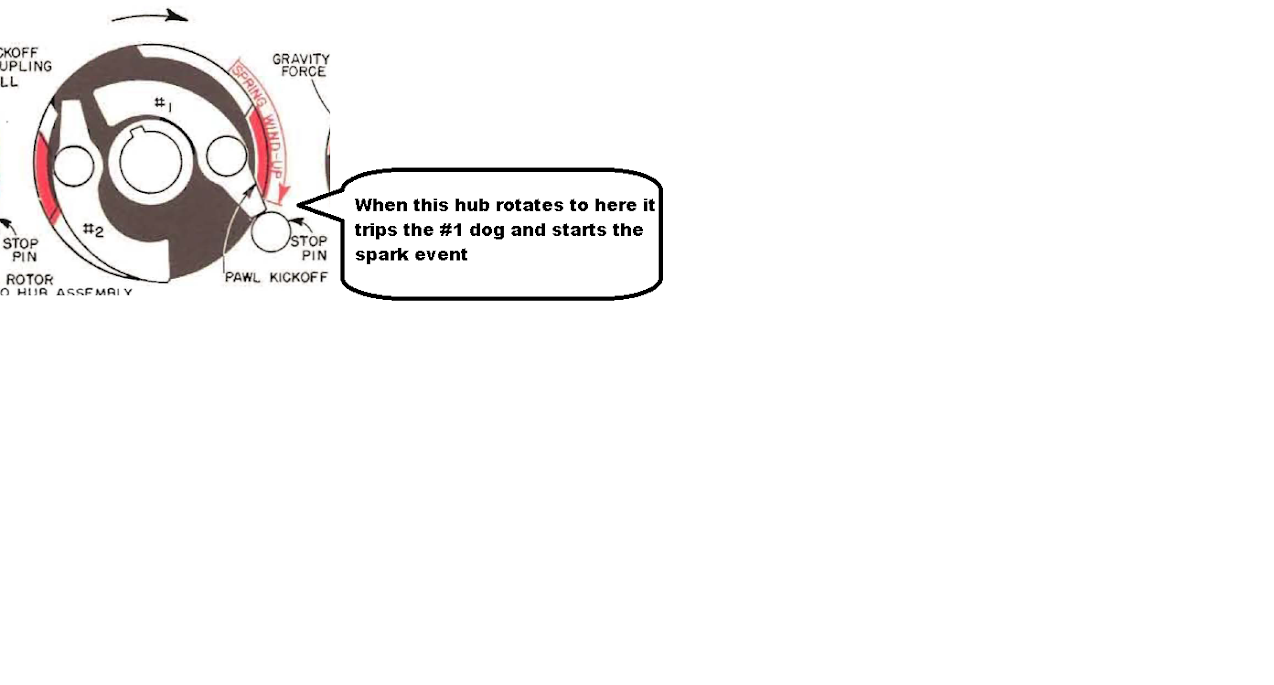

When these engines are put together the magneto is usually a donor from some random application that the engine builder thinks will work. I got to looking at the slick mag on my 4 banger and it is labeled 15 deg. lag angle. so with the mag timed at 28 deg. BTDC if you do the math this means that by turning the prop slowly through by hand the plug will fire at about 13 deg. BTDC. You can see why it would want to snach on ya.I started looking at ways to delay the start timing without changing the run timing. You can order a new drive housing for the impulse coupler that has a different lag angle but I figured if I do that I will end up just trashing the one I have so there is not much to loose if I modify it.

I wanted the mag to fire right at TDC.

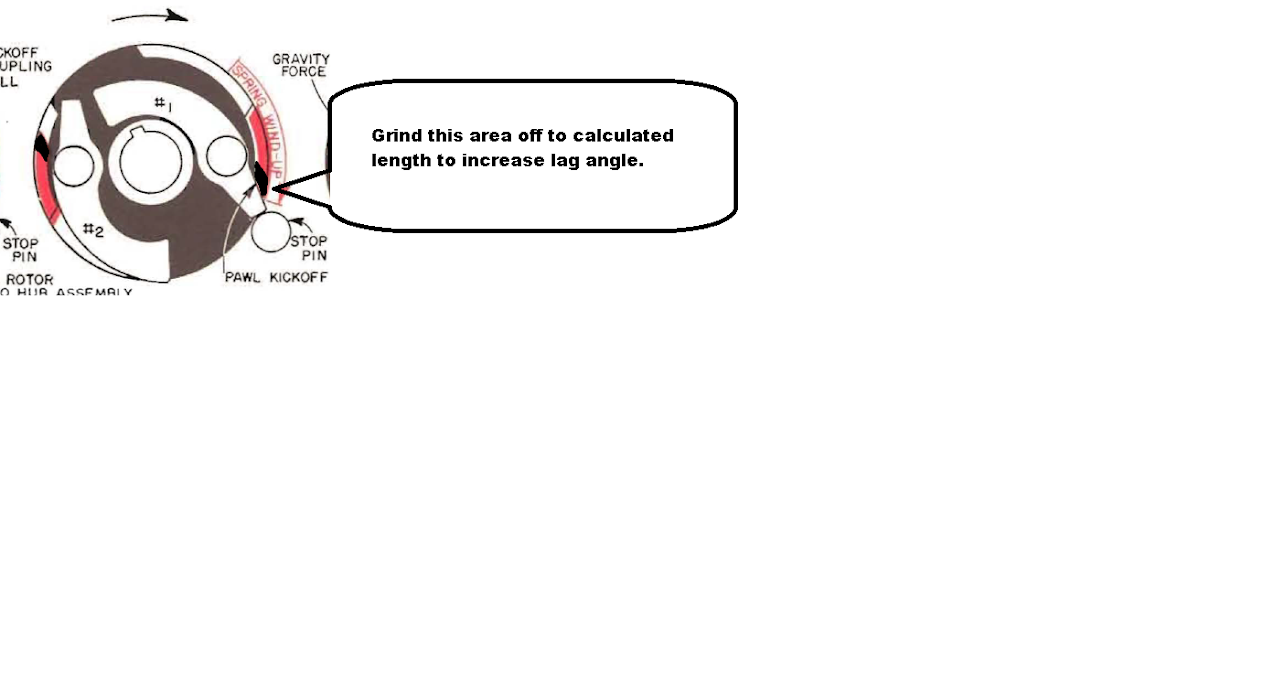

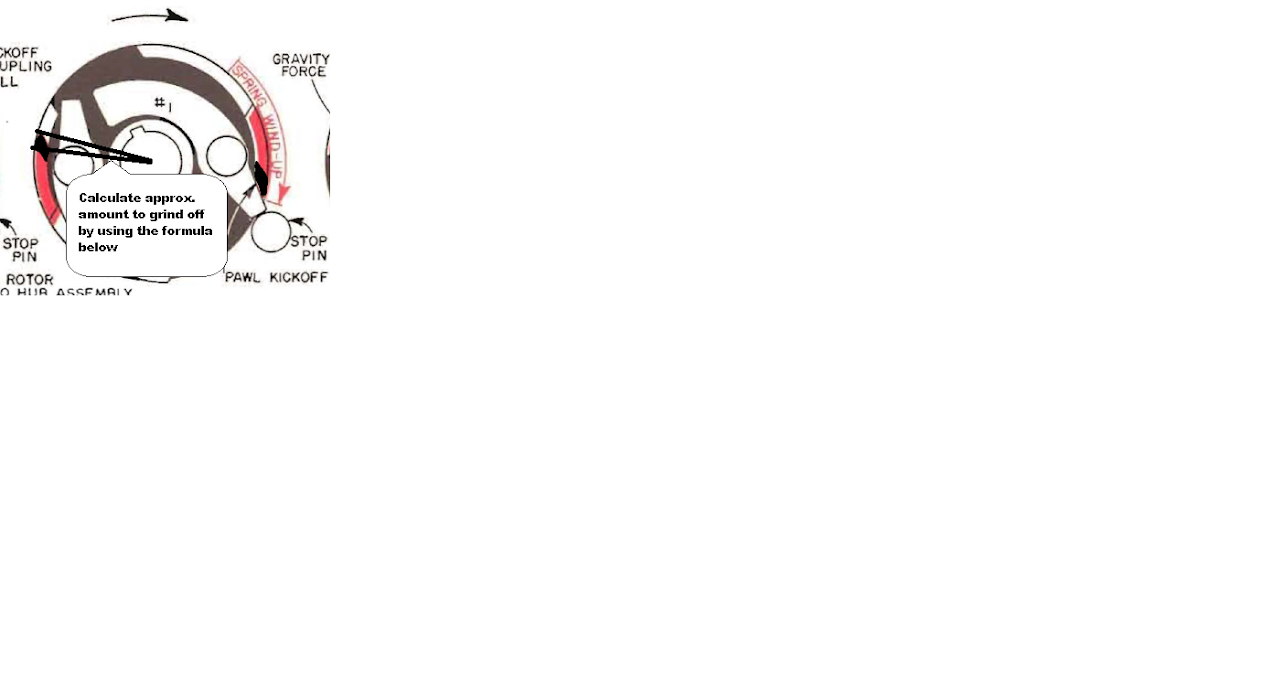

By doing some calculating. I came up with the amount to grind off the drive coupling.

I measured the radius of the circle and then used 13 deg for my triangle (the amount of additional lag I needed) then solved for the opposite leg. This gave me the amount to grind off.

But wait! once you start grinding it off you no longer have something to measure off of to gauge how far you have gone. So measure the entire length of the "trip ear" in its original state then subtract the amount you calculated to remove. This will then be the length that you want the "trip ear" to be when you are finished. Just carefully grind it off and try to retain the original contact angle when you grind so that it wears nice on the impulse dog.

Works great now. No kickbacks. I checked the Fairbanks mag on the LE and it was the same way. Went ahead and did the mod to it.

Good luck.